STATE OF ART LAB

WE ARE LONG-TERM PARTNERS WITH THE WORLD’S LEADING FIBER AND YARN SUPPLIERS. WE WORK CLOSELY WITH THEM O BRING ADVANCED AND CUSTOMIZED SOLUTIONS IN FABRICS AND APPAREL.

BEST TESTING EQUIPMENT IN OUR ACCREDITED LABORATORIES, MEETING AND EXCEEDING ASTM, AATCC AND ISO 14001 STANDARDS, CAN CHECK THE NEWEST MATERIALS PERFORMANCES.

OUR LAB ALLOWS US TO TEST ALL FABRICS BEFORE, DURING AND AFTER BULK PRODUCTION.

ALL QUALITIES GO THROUGH THE LAB FOR BOTH CHEMICAL AND PHYSICAL PERFORMANCE CHECKS.

DATA-COLOR SPECTROPHOTOMETERS FOR FASTER AND MORE ACCURATE COLOR MATCHING AND SPECIFIC SOFTWARE ALLOWS US OPTIMAL DYEING COST MANAGEMENT AND QUALITY.

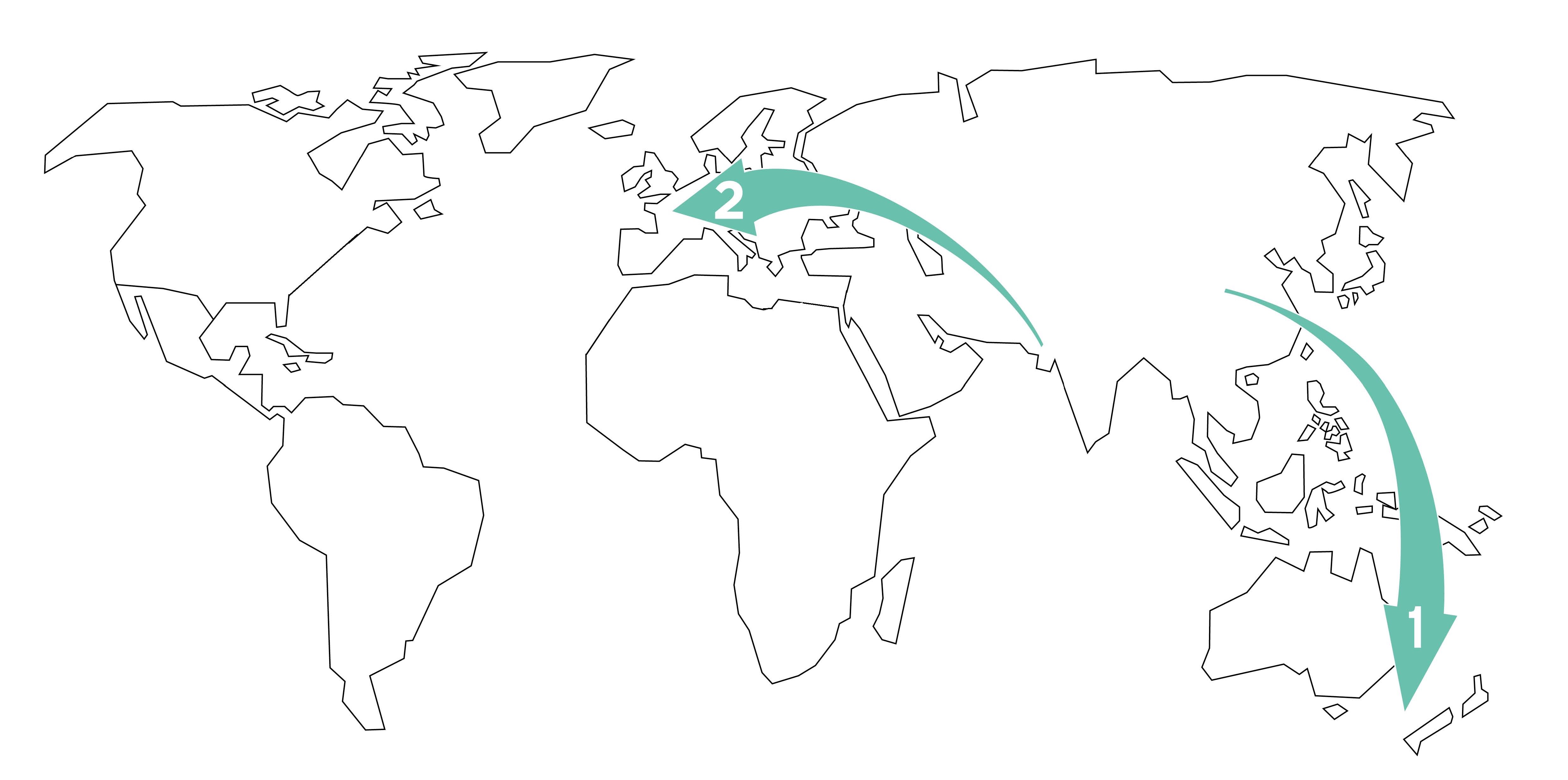

LOGISTIC SYSTEMS

CHALLENGE HAS A DEDICATED LOGISTICS TEAM AND IT PLAYS A VITAL ROLE IN A LEAN SUPPLY CHAIN. CHALLENGE PROVIDES A PICK AND PACK SERVICE TO KEY ACCOUNT

CUSTOMERS. WE PACK AND DISTRIBUTE TO THE EXACT REQUIREMENT OF EACH RETAIL DESTINATION.ENHANCED EFFICIENCY AND INCREASED

PRODUCTIVITY EASE PRESSURE ON STOCK-HOLDING COSTS

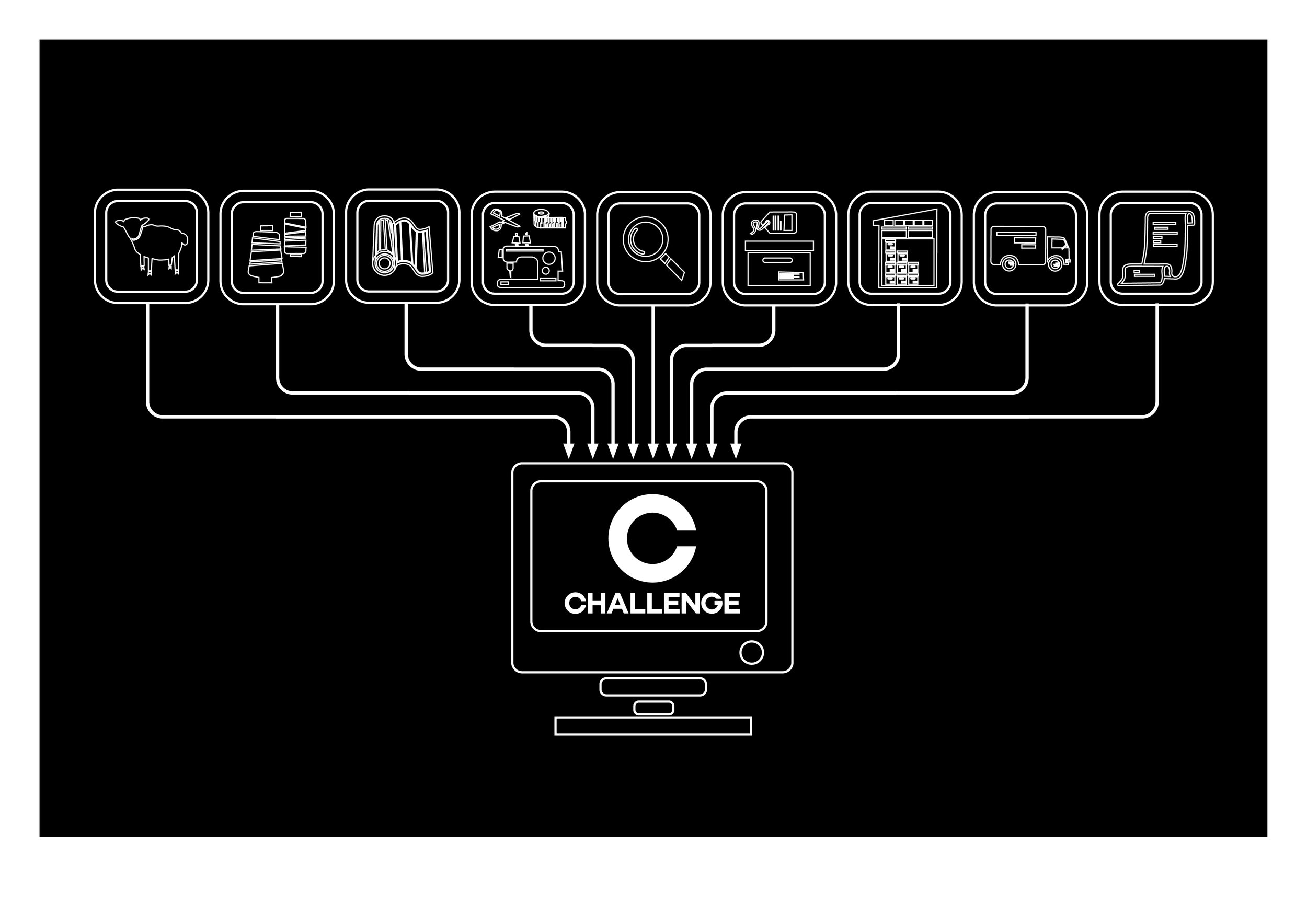

INFORMATION SYSTEMS

CHALLENGE INFORMATION SYSTEMS DELIVER REAL BUSINESS ADVANTAGES.OUR TRACEABILITY, E-COMMERCE AND PROCESS CONTROL ALLOW YOU TO

MONITOR EVERY STAGE OF THE PRODUCT CREATION. THE CHALLENGE ERP SYSTEM IS INTEGRATED INTO OUR PRODUCTION-MANAGEMENT

WORK-FLOW PROVIDING INFORMATION ON:THE RAW MATERIAL SUPPLY, FIBER SOURCING, CONTROL OF STANDARDS AND

QUALITY IN MANUFACTURING, THE PACKING, STOCK DELIVERY AND CUSTOMER SERVICES.

RESPONSIBLE MANUFACTURING

SYSTEMS

IN 2010 CHALLENGE TEXTILE WAS HONORED TO BE THE FIRST BLUESIGN SYSTEM PARTNER IN MAINLAND CHINA.SINCE THEN WE HAVE BEEN ACCREDITED WITH CERTIFICATION

FROM ORGANIZATIONS MAINTAINING STANDARDS ACROSS SUSTAINABLE AND RESPONSIBLE MANUFACTURING INITIATIVE.WE ARE PROUD OF OUR COMMITMENT TO THE

INVESTMENT IN ENERGY SAVING INITIATIVES AND CLEAN PRODUCTION SYSTEMS.